End-to-End Ownership of Solution Development, Product Quality, and In-Field Performance

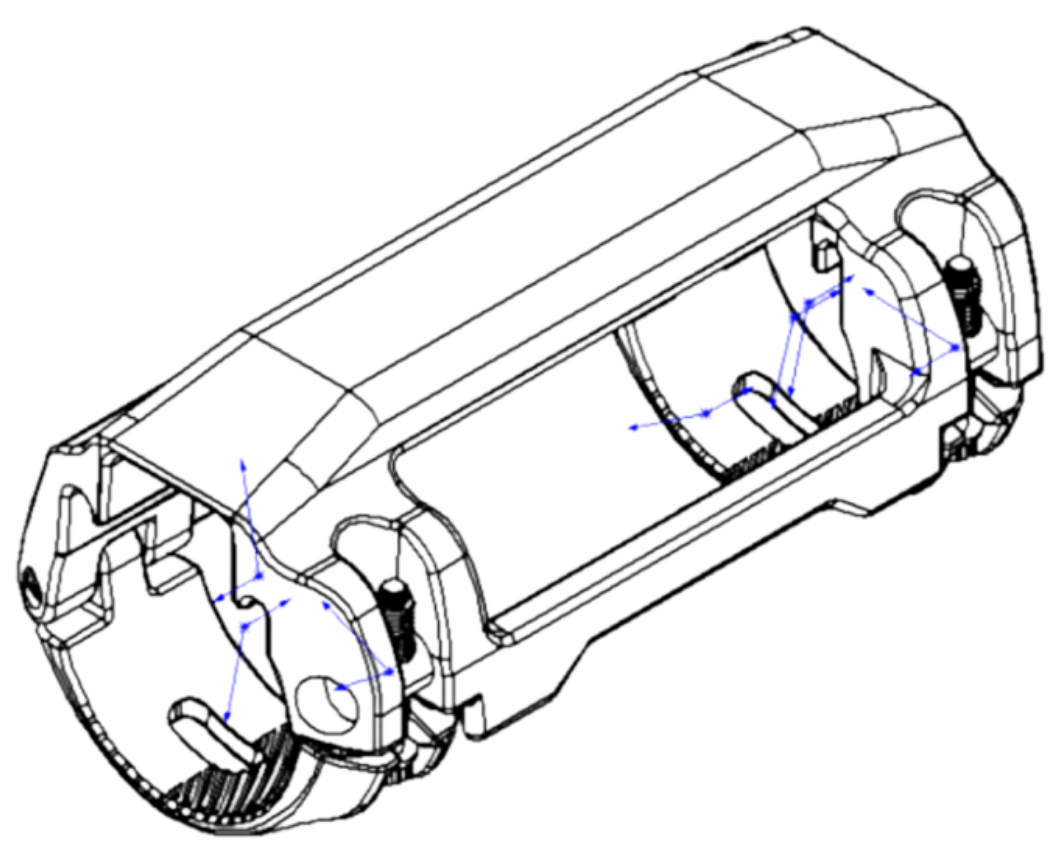

HULK is the leading provider of engineered solutions for the toughest unconventional well production issues in the United States and Canada. Our difference is we answer the phone and can rapidly develop custom solutions for operators large and small. Our Refurbishment Program allows you to reuse our cable protection technology over and over again, helping you to save money and increase ROI.

HULK is the partner you need to handle all aspects of product design, development, delivery, installation, refurbishment, and storage so you can focus on ALS optimization and production.

HULK Installations

HULK’s main focus in the field is on safety, communication, and education to ensure the correct use of SKUs and proper installation of our cable protection technology. HULK technicians are trained to deliver high quality customer service to decrease downtime and get our products installed quickly so you can begin production. When it is time to pull products, HULK will pick up your clamps for refurbishment and store them until you need them again.

Engineering Custom Solutions

You have production issues, HULK has solutions. Our in-house engineering team has the capacity for the rapid development of custom products that meet your specific applications and needs. We have 3D printing and CNC machining capabilities at our Houston headquarters, which means you can call us with any production issue and we can design, develop, and deliver a solution faster than anyone else.

If HULK can solve a problem for you, please contact our engineering team directly so we can get started designing a solution: 307-699-3198.

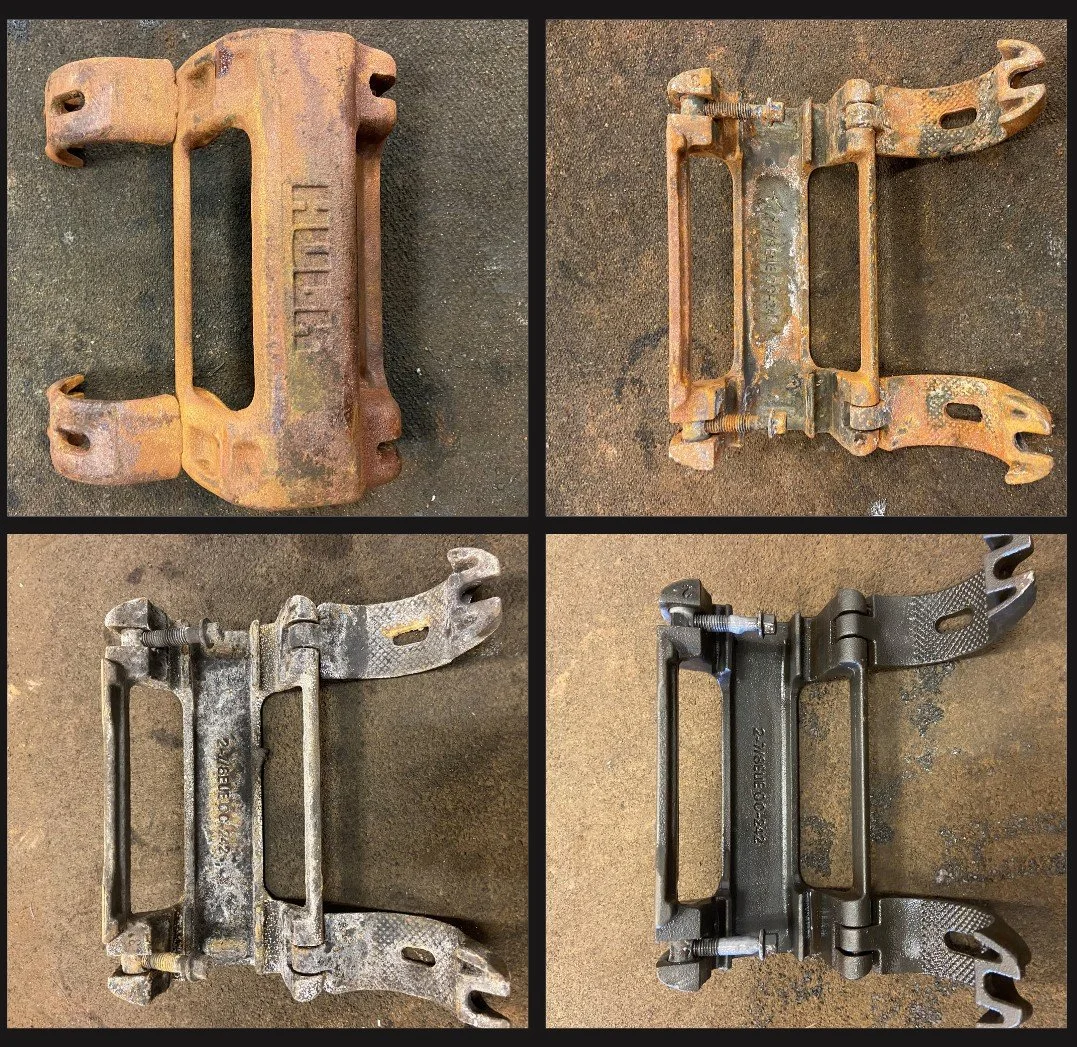

HULK ReFURBISHMENT

HULK Refurbishment is one of the major cost-saving benefits of using HULK cable protection products. Our clamps are fully refurbishable, and HULK will return used clamps to working condition and reinstall them over and over again.

HULK Refurbishment benefits include:

Stamp of approval for all refurb products

Full inspection and cleaning

Re-lubrication or full replacement of bolts/barrels to ensure seamless installation

Inventory management at our facility

Complete installation history

Post-run reports detailing run conditions